Products

Home Products

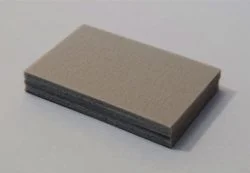

CERAMAR is a flexible foam expansion joint filler composed of a unique synthetic foam of isomeric polymers in a very small, closed-cell structure. Gray in color, CERAMAR is a lightweight, flexible, highly resilient material offering recovery qualities of over 99%. The compact, closed-cell structure will absorb almost no water. USES CERAMAR flexible foam expansion joint filler provides an excellent joint filler and back-up material for use in either horizontal or vertical applications where expansion and contraction movements must be accommodated. CERAMAR is compatible with all currently popular cold-applied sealants, caulks, and hot-pour joint sealing compounds. It is lightweight and easy to cut or form in the field without waste. CERAMAR compresses easily for use with shrinkage-compensating concrete and it may be used to relieve stress and pressure in concrete pavements. FEATURES/BENEFITS May be sealed with hot- or cold-applied sealants. User friendly, lightweight, flexible foam…forms or wraps around curved or circular surfaces. Cuts easily on the job with a razor knife…no breakage or waste. Offers high resiliency and 99% recovery qualities…low compression values…non-extruding…minimal water absorption. Resists ultraviolet degradation…will not rot or deteriorate. Non-impregnated…no staining or bleeding. Bonds easily with common cartridge adhesives. Non-gassing. SPECIFICATIONS ASTM D 5249, Type 2 ASTM D 1752, Sections 5.1 – 5.4, with compression requirement modified to 10 psi (7.03 g/mm²) minimum and 25 psi (17.58 g/mm²) maximum. ASTM D 7174-05 LEED INFORMATION May help contribute to LEED credits: MR Credit 5.1: Regional Materials: 10% Extracted, Processed & Manufactured Regionally MR Credit 5.2: Regional Materials: 20% Extracted, Processed & Manufactured Regionally PACKAGING Furnished in standard sheets 48″ (1.22m) wide, 10′ (3.05m) long. Also available in precut widths of 2″ to 46″ (50.8mm to 1.17m) Our Website

| City | City A | Found Date | 2024-09-30 |

| License Number |